Auto body panel replacement, a complex yet vital process in automotive repair, involves skilled technicians assessing damage, checking compatibility, and using specialized tools for precise removal while preserving surrounding components. Crucial steps include exact alignment to factory specifications and advanced welding techniques for structural integrity. This meticulous approach, emphasizing safety precautions and strict tolerances, restores vehicles to their pre-accident condition, enhancing both aesthetic value and driving safety, key aspects in collision repair, auto body painting, and frame repair. Regular body panel checks are recommended for proactive auto maintenance.

In the realm of automotive repair, auto body panel replacement is a meticulous process that demands precision and expertise. This article explores the art of welding and alignment, crucial aspects that ensure the structural integrity and aesthetic appeal of vehicle repairs. From understanding the fundamentals to mastering advanced techniques, we guide you through every step, emphasizing the importance of proper welding and alignment for long-lasting, high-quality auto body panel replacement results.

- Understanding Auto Body Panel Replacement: The Basics

- The Importance of Proper Welding and Alignment Techniques

- Step-by-Step Guide to Effective Auto Body Panel Replacement

Understanding Auto Body Panel Replacement: The Basics

Auto Body Panel Replacement is a critical process in automotive repair and restoration, focusing on restoring damaged or distorted exterior panels to their original condition. This involves skillfully removing and replacing various components like doors, fenders, hoods, or trunks, ensuring seamless integration with the vehicle’s existing structure. The precision and expertise required for this task are immense as even a minor misalignment can impact the overall aesthetics and safety of the vehicle.

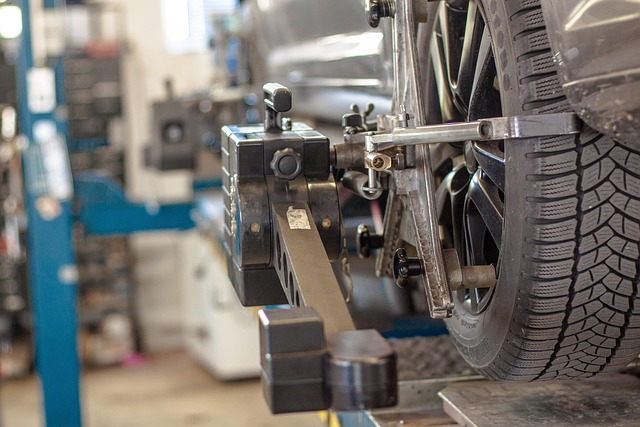

The process begins with meticulous preparation, including assessing the damage, gathering the necessary replacement parts, and ensuring compatibility. Skilled technicians then employ specialized tools and techniques to carefully disconnect and remove the damaged panel while maintaining the integrity of surrounding panels and structural components. Once the old panel is replaced with a new one, precise alignment is crucial to match the original factory specifications, ensuring proper fitment and a seamless finish. This often involves advanced equipment for measuring and adjusting, guaranteeing that the auto body painting and final assembly are flawless, mirroring the vehicle’s pre-accident condition, and enhancing its overall safety and value through comprehensive automotive collision repair.

The Importance of Proper Welding and Alignment Techniques

Proper welding and alignment techniques are paramount in auto body panel replacement, ensuring the structural integrity and aesthetic appeal of vehicles. When replacing panels, especially after damage from accidents or dents, precise alignment is key. Even minor misalignments can lead to visible gaps or uneven surfaces, compromising the vehicle’s overall appearance and safety.

Skilled technicians employ advanced tools and methods to guarantee accurate welding and alignment. This involves careful measurement, utilization of reference points, and adherence to strict tolerances. The goal is not just to fix the panel but to restore the vehicle to its pre-incident condition, seamlessly blending new with old and ensuring a flawless finish that enhances the car’s overall value, both aesthetically and in terms of safety during driving, for auto body panel replacement, vehicle paint repair, or auto frame repair processes.

Step-by-Step Guide to Effective Auto Body Panel Replacement

Step-by-Step Guide to Effective Auto Body Panel Replacement

The process of replacing an auto body panel requires precision and care. Begin by assessing the damage, gathering necessary tools like welding equipment, and ensuring proper safety measures are in place. Next, remove any debris or remaining parts from the damaged area, using a hammer and chisel if needed. This step ensures a clean and accurate measurement for the new panel.

Measure the opening precisely to get the right fit for the replacement panel. Mark the outlines clearly, then cut out the old panel with a metal cutter or plasma torch. Fit the new panel into place, aligning it carefully with existing panels using markers or alignment tools. Secure the new panel with temporary clamps, then weld along the edges, making sure each joint is strong and sealed. Finally, inspect the work for any gaps or misalignments, making adjustments as needed before proceeding with finishing touches, such as priming and painting, to match the vehicle’s original appearance. Regular auto maintenance includes checking body panels for signs of wear, ensuring prompt replacement where necessary.

Auto body panel replacement is a precise process that demands skilled technicians and meticulous attention to detail. By employing proper welding and alignment techniques, as discussed in this article, professionals can ensure not only structural integrity but also a seamless finish. Understanding the basics and following a step-by-step guide are key to achieving high-quality results, ultimately enhancing vehicle safety and aesthetics for years to come.