Technicians meticulously measure and study vehicle dimensions using advanced tools like laser scanners and digital angle gauges before auto body panel replacement to ensure accurate fitting, structural integrity, and aesthetic appeal. They carefully mark cut lines and use specialized software for precise alignment, preventing future issues and maintaining vehicle quality for optimal performance and driving experience.

In the intricate process of auto body panel replacement, technicians play a pivotal role in ensuring the new component seamlessly integrates with the vehicle’s structure. This article delves into the meticulous techniques employed by these experts to maintain precise dimensions and specifications. From understanding the nuances of auto body panel measurements to mastering alignment during installation, we explore the critical steps guaranteeing a perfect fit, enhancing both safety and aesthetics in the automotive repair landscape.

- Understanding Auto Body Panel Dimensions and Specifications

- Techniques for Measuring and Marking Panels Accurately

- Ensuring Proper Alignment and Fitting During Installation

Understanding Auto Body Panel Dimensions and Specifications

Before any auto body panel replacement takes place, technicians must first have a thorough understanding of the vehicle’s dimensions and specifications. This includes accurately measuring the size and shape of each panel, as well as its unique curves and contours. This meticulous process is crucial in ensuring that the new panel seamlessly fits into the existing car structure, aligning perfectly with other components like doors, hoods, and fenders.

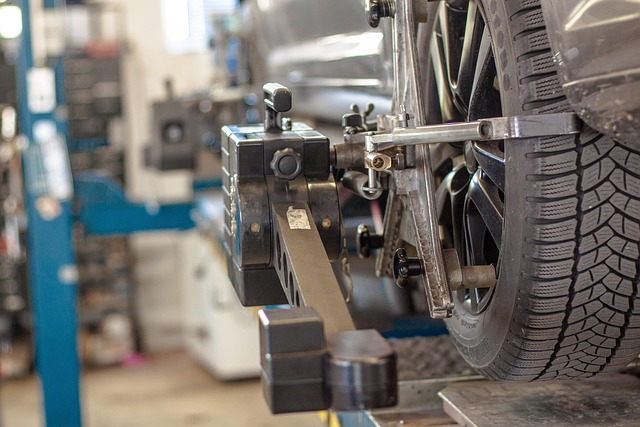

Technicians refer to detailed vehicle repair manuals and manufacturer specifications to gather this vital information. They use advanced measuring tools and software to capture precise data, accounting for any variations caused by different models, years, or even minor modifications. This level of precision is essential in the collision damage repair process, where fitting new panels accurately means preventing further structural weaknesses or aesthetic imperfections in the car repair services.

Techniques for Measuring and Marking Panels Accurately

Technicians employing precise techniques for measuring and marking auto body panels ensure accurate cuts during replacement, minimizing errors that could compromise the structural integrity of the vehicle. They utilize specialized tools like laser measurements and digital angle gauges to capture exact dimensions, accounting for variations due to manufacturing tolerances and potential hail damage repair needs. These instruments facilitate seamless integration of new panels with existing components in the auto repair shop or vehicle body shop environment.

Furthermore, skilled technicians may employ marking techniques such as stenciling or marking with specialized pens to clearly indicate cut lines, bolt holes, and other critical reference points. This meticulous approach ensures that every panel is installed correctly, aligning with safety standards and aesthetic expectations for a seamless finish in auto body panel replacement processes.

Ensuring Proper Alignment and Fitting During Installation

When carrying out an auto body panel replacement, technicians must meticulously ensure proper alignment and fitting during installation. This crucial step goes beyond merely attaching the new panel to the vehicle’s frame. It involves precise measurements, careful adjustments, and the use of specialized tools to match the original contours and curves of the auto body. Technicians employ a variety of techniques, including laser measuring devices and computer-aided design (CAD) software, to guarantee that each panel fits seamlessly, maintaining the structural integrity and aesthetic appeal of the vehicle.

Proper alignment is paramount to prevent future issues like rattling or misalignment that could arise from improper installation. Moreover, it ensures that the auto body retains its safety standards, particularly in the event of another fender bender or automotive collision repair. This meticulous attention to detail not only enhances the vehicle’s overall quality but also prolongs its lifespan, ensuring optimal performance and a satisfactory driving experience for the owner.

When technicians follow precise measurement, marking, and alignment techniques during auto body panel replacement, they ensure a seamless fit that restores structural integrity and aesthetic appeal to damaged vehicles. By understanding dimensional specifications, employing accurate tools, and paying meticulous attention to detail throughout the installation process, they deliver high-quality repairs that meet industry standards. These practices not only guarantee customer satisfaction but also contribute to safer driving conditions.